Unloading Serving Robot

Overview

The unloading serving robot (USR) is a robot designed to autonomously complete indoor last-mile delivery services. It adds to current serving robots the capability to unload a payload from the robot's internal storage to the ground.

I completed this project for an 11-week summer internship with the Mechatronics Lab at Bear Robotics in Seoul, South Korea.

Contributions

I designed and built this prototype mostly independently, with some input from my Mechatronics coworkers. My work included:

-

Conducting background research for project initiation

-

Designing a full system model in Solidworks

-

Selecting appropriate mechanisms, structural components, and motors

-

Creating smaller prototypes for critical subsystems

-

Coding the system as a state machine in Arduino

-

Fabricating the final prototype in lab

-

Presenting my work at an all-hands company meeting

Skills

project organization | Solidworks | prototyping | 3d printing | engineering drawings | Arduino

Motivation

Current serving robots are used primarily for transportation and do not have the capability to unload their payload without external assistance. Unloading capabilities are needed in industries such as logistics and delivery. With the increasing demand for delivery services (e.g., Amazon, DoorDash), companies are seeking ways to maximize the efficiency of last-mile delivery.

I chose to focus on indoor delivery of small- to medium-sized packages, such as food deliveries. This is particularly applicable in highly-dense urban areas, where delivery workers currently spend valuable time and effort to sort and deliver hundreds of packages or food deliveries in large apartment buildings.

Mechanism Selection

I researched existing technologies to determine which mechanism would be suitable for the USR system. I identified unloading or vertical motion mechanisms from dozens of existing machines, categorizing them into mechanism types. I organized these into a spreadsheet to compare them according to relevant criteria.

I presented these results along with simple concept diagrams at our Mechatronics team meeting. We decided to pursue a vertically-actuated roller conveyor system due to its relative simplicity, cost-effectiveness, and compactness.

Notes from mechanism research and concept comparison. Selection criteria chosen based on application and feasibility.

I performed a separate analysis to determine the specific linear actuator type for the vertical actuator mechanism. I concluded that a ball screw would be optimal for my application due to its high load capacity, durability, precision, and efficiency.

I also chose a stepper motor to operate the ball screw. I calculated the maximum required torque for a payload up to 10kg and found an appropriate stepper motor to use from our existing inventory.

In addition to vertical actuation, we needed an actuator in the horizontal plane to allow the robot to unload objects from the elevated base unit directly to the ground. After sketching a few concept ideas, we decided to explore two ideas in parallel: a horizontal linear actuator, which my coworker designed, and a hinge mechanism, which I designed.

Hinge Prototype

I sketched a few different concepts for the hinge and decided to design it as a linkage for simplicity and mechanical advantage.

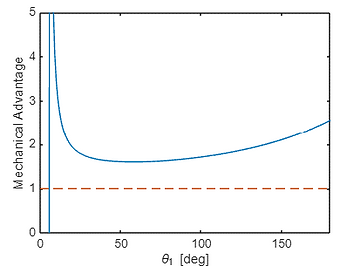

I drew a diagram of the linkage mechanism and calculated a formula to determine the mechanical advantage at the output as a function of angle and linkage arm lengths.

I coded a script in MATLAB (and translated to Python for accessibility) to determine the optimal geometry for the hinge to provide the maximum mechanical advantage for a 90-degree range of motion.

Based on my calculations of the mechanical advantage and output torque required to operate the door, I calculated the desired input torque to power the hinge. From this and an estimate of the desired angular speed, I selected a motor that fit my desired specifications.

I then designed a model of the hinge (including motor mount and linkage) in Solidworks. I printed my design on a Prusa i3 MK3S+ (FDM) 3d printer and assembled the linkage. I also in-corporated photosensors to act as limit switches at the endpoints of the hinge's range of motion.

I programmed an Arduino state machine to control the opening and closing of the hinge. I also added speed control to prevent the hinge from moving too quickly.

Hinge prototype demo (2x speed). Arduino state machine with photo-sensors for limit detection.

CAD Model and Overall Design

I designed a CAD model for the USR system in Solidworks. This model helped me determine the geometry of the system, visualize how each part would move, and identify issues such as poor structural support or interference between components.

Actuated hinge linkage mechanism

Stepper motor attached to ball screw via belt

Photosensors for level detection

Aluminum profiles supplied from external vendor

Included additional supports during fabrication for rigidity

Platforms to store items inside robot body

Roller platform attached to ball screw vertical actuator

Existing robot base unit

Electronics housings

(green components custom designed and 3d printed)

Fabrication

While the majority of the model translated directly to the physical prototype, I also had to make some modifications throughout the fabrication process, such as adding extra beams for structural support, adjusting press-fit dimensions of 3d-printed parts, customizing housing for the electronics and battery, and accounting for deflections.

Most of the structural components were aluminum profiles, which I custom-ordered from an external vendor using engineering drawings I created in Solidworks. I also selected and ordered bearings, bolts, nuts, and brackets according to the load specifications and model geometry.

For more customized components, I designed the parts and 3d printed them in-house using FDM printers (Prusa i3 MK3S+ and Anycubic Kobra 2 Max).

Sample engineering drawing for aluminum profile to order from external vendor:

Custom jig to align drill centers on 40mm profiles. Diamond-shaped holes align with measuring lines for center punch through circular hole.

Due to time constraints with ordering, I also ended up using machines and hand tools to improvise some parts from what materials we had. For example, I needed to adjust some profiles but didn't have access to a mill (or a bandsaw), so I measured and cut existing profiles by hand. I also designed and 3d printed a jig to measure and drill the profiles as precisely as possible manually.

While I enjoyed the building process of this project, in hindsight I should have considered design for assembly principles to make the fabrication process more efficient. This was meant to be more of a "pretotype", but if I were to consider how to move this project forward, it would likely require major design changes to make manufacturing more feasible.

Reflections

I successfully completed the working prototype and presented my work at the company's all-hands meeting. However, there is plenty of room for improvement.

My coworkers advised me to make this project a "pretotype" to test the desirability of the USR concept, but it ended up developing in complexity without ever considering the feasibility of the USR as a product. From what I've since learned about product design, proper market and user research before diving into the intricate technical details would have been beneficial.

Also, the design of the system could be improved for manufacturing and assembly as well as quality. Overall, although I did perform calculations for major components, in future iterations, I would revisit and refine some design choices I made more arbitrarily.

USR working prototype demo (4x speed)

This internship came before I took manufacturing or product design classes, so in hindsight I see how that knowledge and experience would have helped the project. Having more mentorship also would have been helpful, since I worked mostly independently on this project and didn't have much guidance from experienced mentors.

However, this was still a good learning experience, especially as it was my first internship. In addition to gaining more technical design proficiency with Solidworks, Arduino, 3D printing, part selection, and physical prototyping, I learned how to work within the organizational framework of a company to effectively initiate, manage, and execute a project from start to finish. I also learned how to apply theoretical mechanical engineering principles to real designs, make informed design choices, and address unexpected problems given limited time and resources.